About OME International

See our manufacturing plant in video on YouTube – https://www.youtube.com/watch?v=dX_XslvINYA

IATF 16949:2016 certified

ISO 13485:2016 certified

ISO 9001:2015 certified

Success Stories

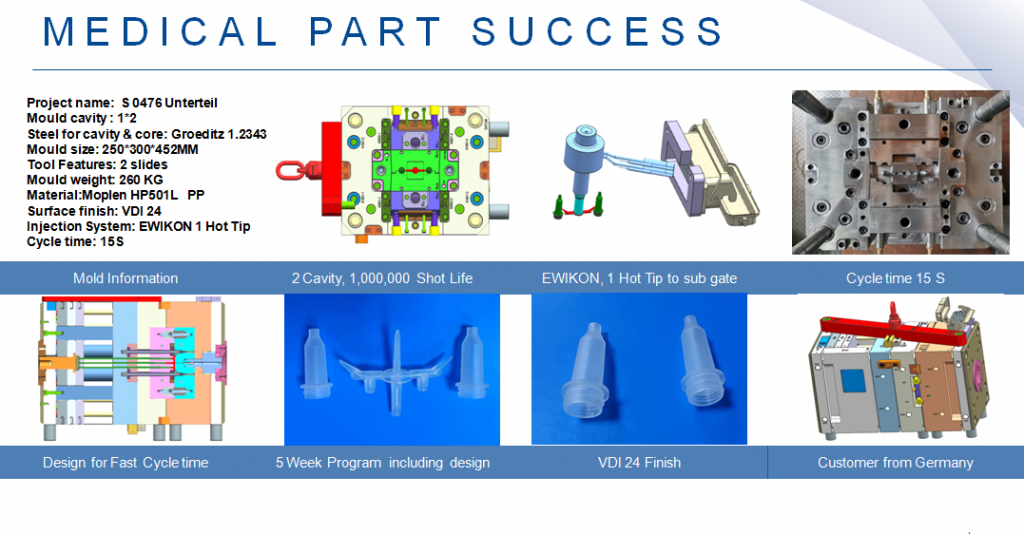

Success Story: Medical Part

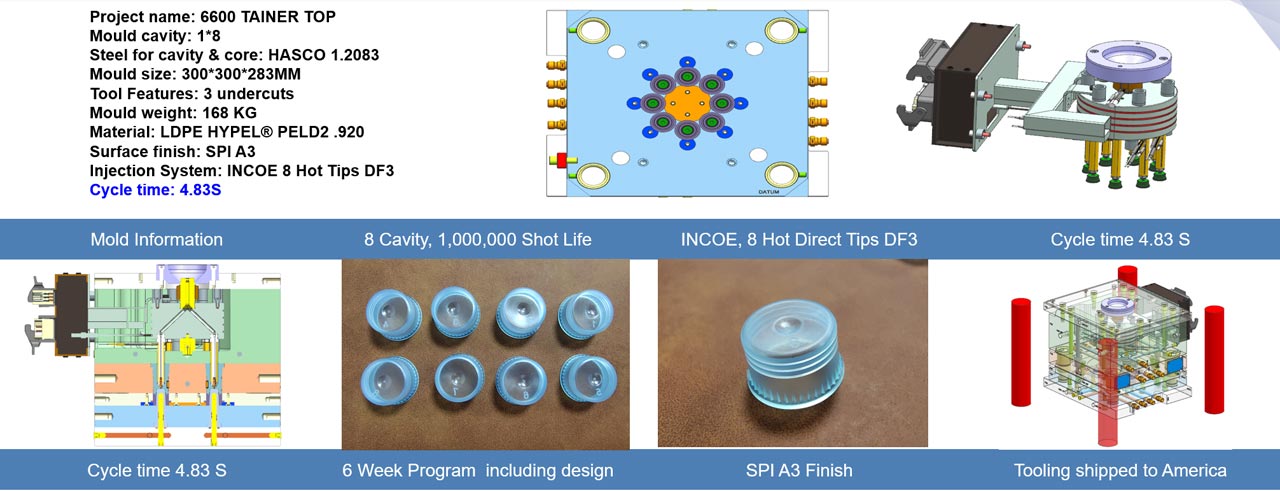

Success Story: 5 Second Cycle

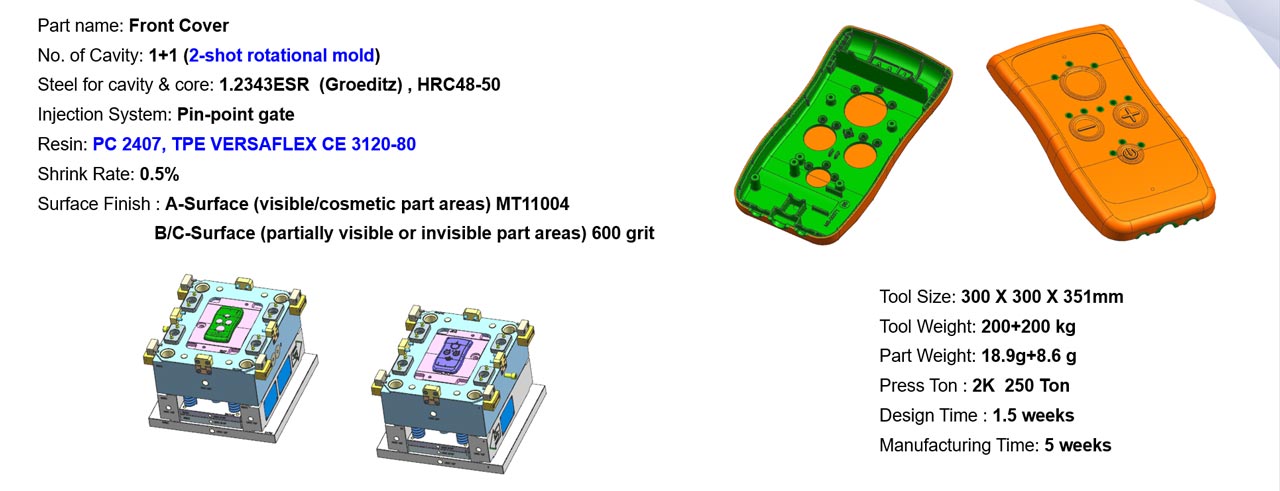

Success Story: 2-Shot Medical

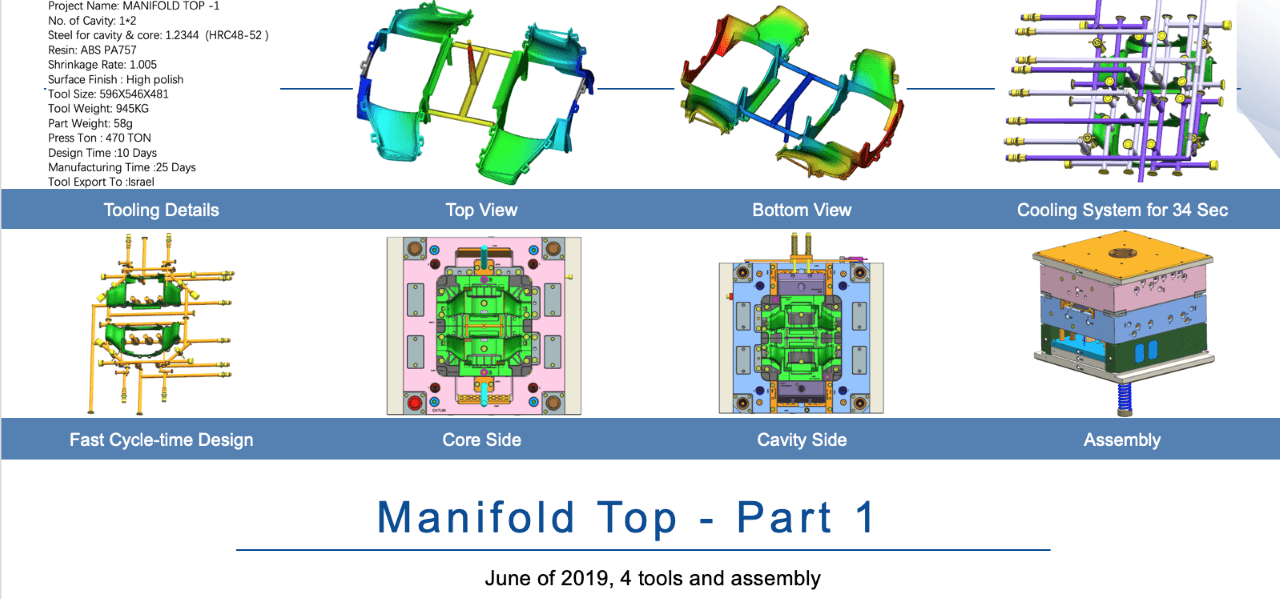

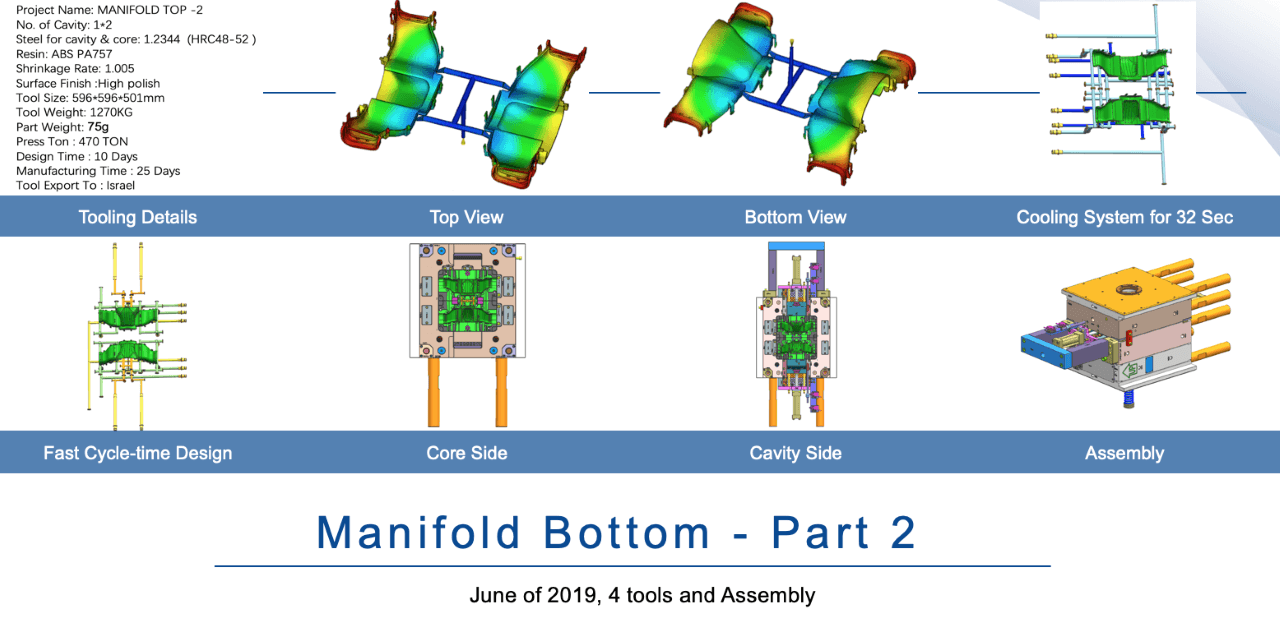

Success Story: Assembly of Manifold Top

OME build all 4 tools and supplies the subassembly to final customer in Israel.

We can help our customers by supplying single molded parts or by providing assembly services.

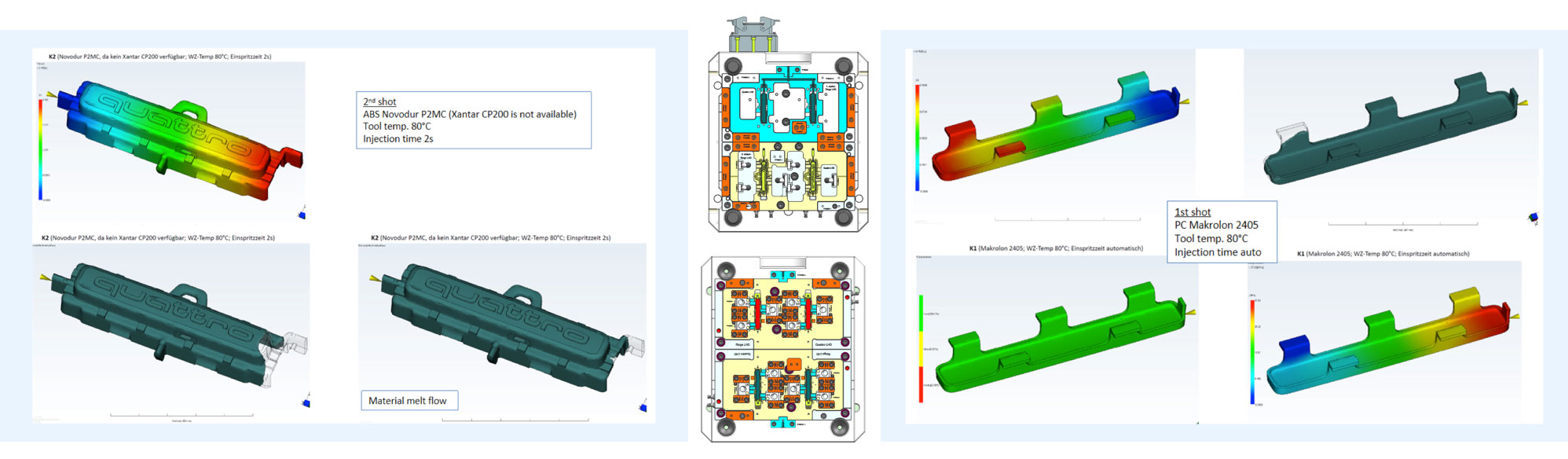

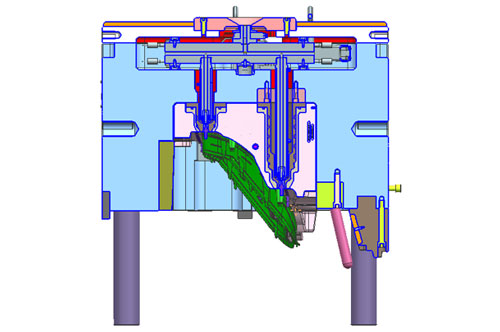

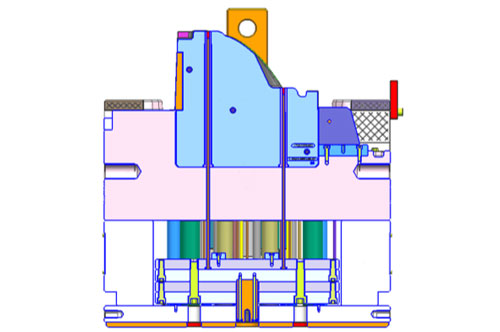

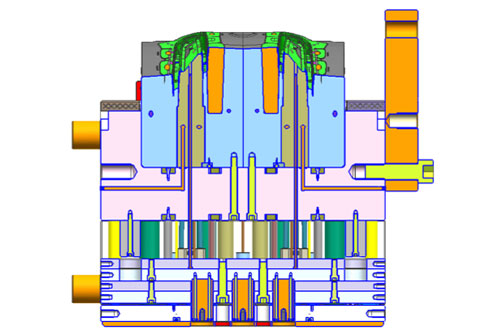

Success Story: 2K Rotational Success

Part name: Car brand lamp

No. of Cavity: 1+1, (2-shot rotational mold)

Steel for cavity & core: 1.2343ESR (Groeditz) , HRC50-52

Injection System: Hotrunner connector configuration (INCOE)

Resin: ABS/PC & PC

Shrinkage Rate: 0.55%

Surface Finish : A-Surface (visible/cosmetic part areas) 1000 grit

B/C-Surface (partially visible or invisible part areas) 600 grit

Tool Size: 396 X 446 X 375mm

Tool Weight: 400 kg

Part Weight: 8 g

Press Ton: 110 Ton

Design Time: 2 weeks

Manufacturing Time: 5 weeks

Export: Germany, December 1, 2018

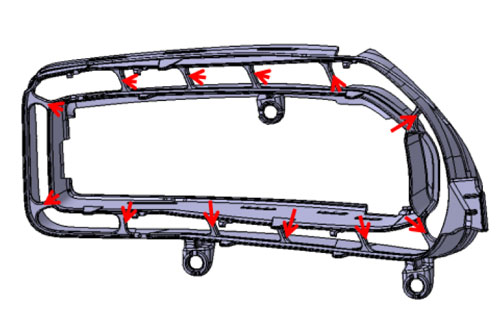

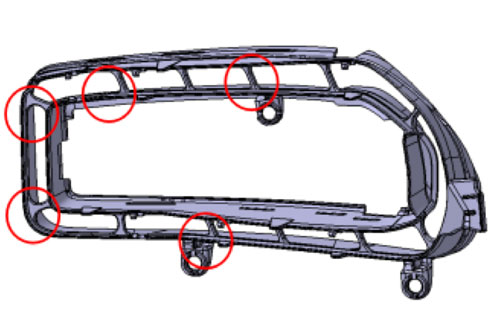

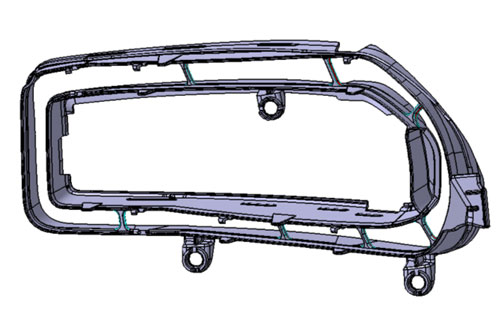

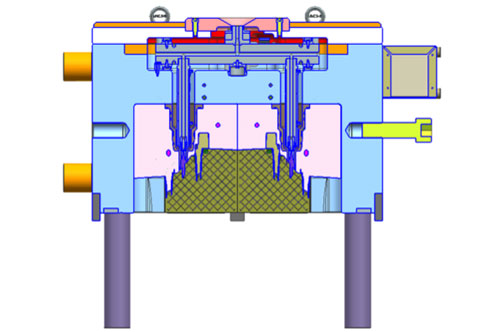

Success Story: Automotive Light Housing

December of 2018, complete program in 8 weeks including design and adjustments after T1. Program shipped to Germany for production after Trial 2.

Our recommendations resulted in elimination of distortion during ejection and reduced cycle time.

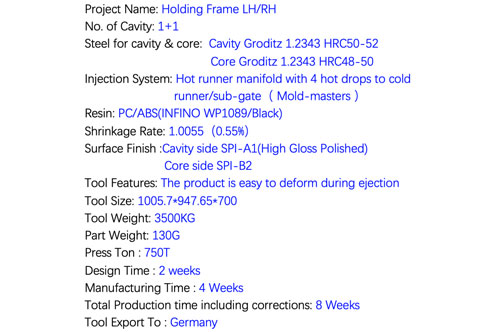

Success Story: Multi-cavity Tool Sucess

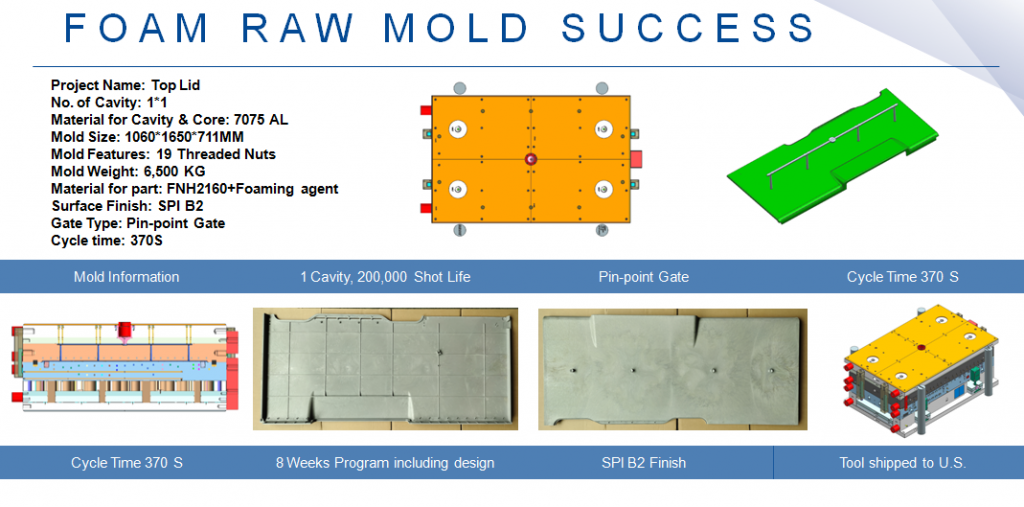

Success Story: Foam Raw Mold Success