About OME International

Success Stories

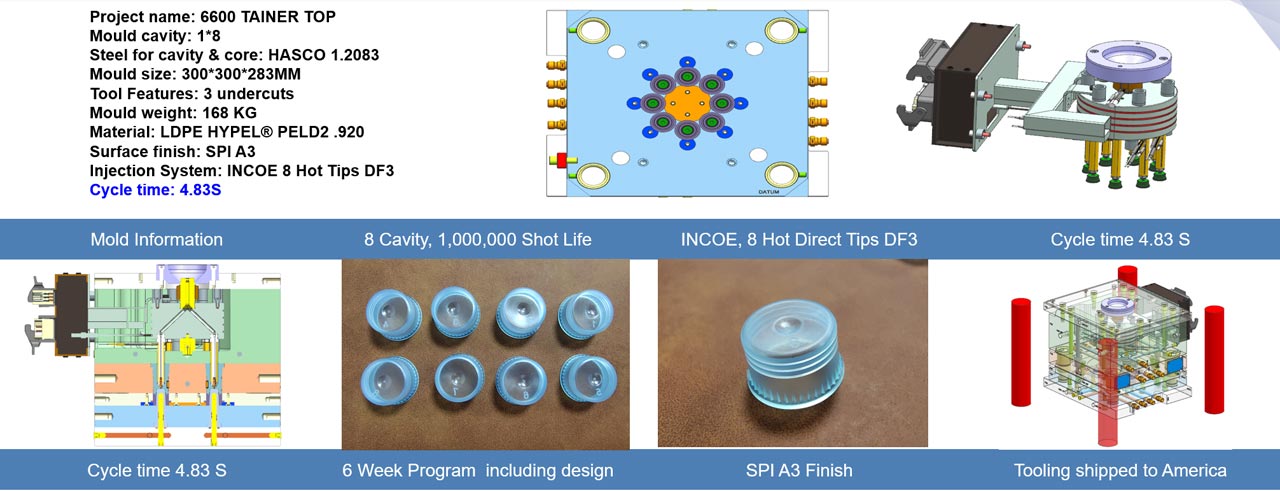

Success Story: Medical Part

Success Story: 5 Second Cycle

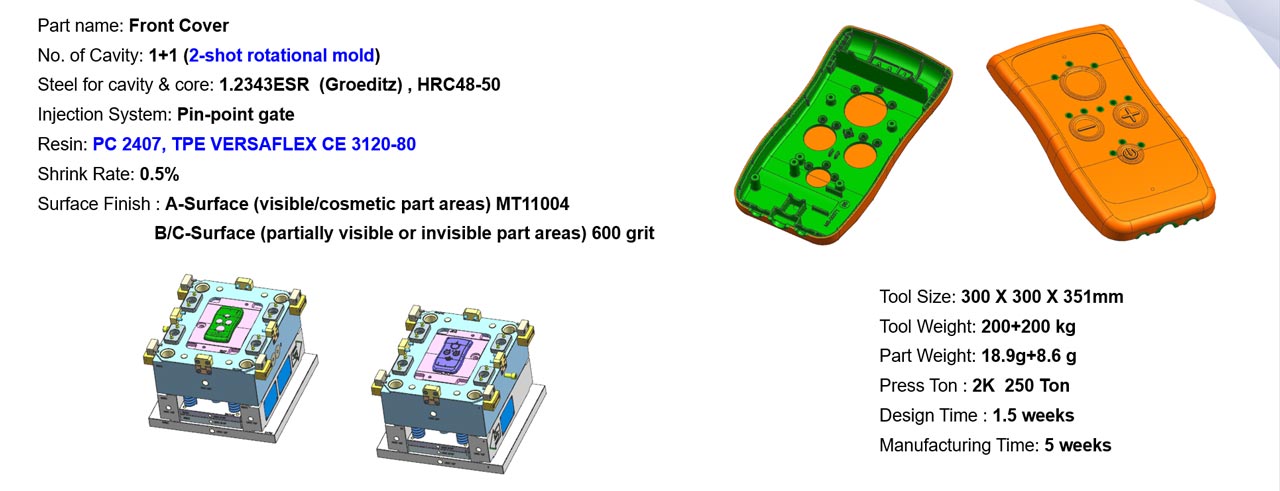

Success Story: 2-Shot Medical

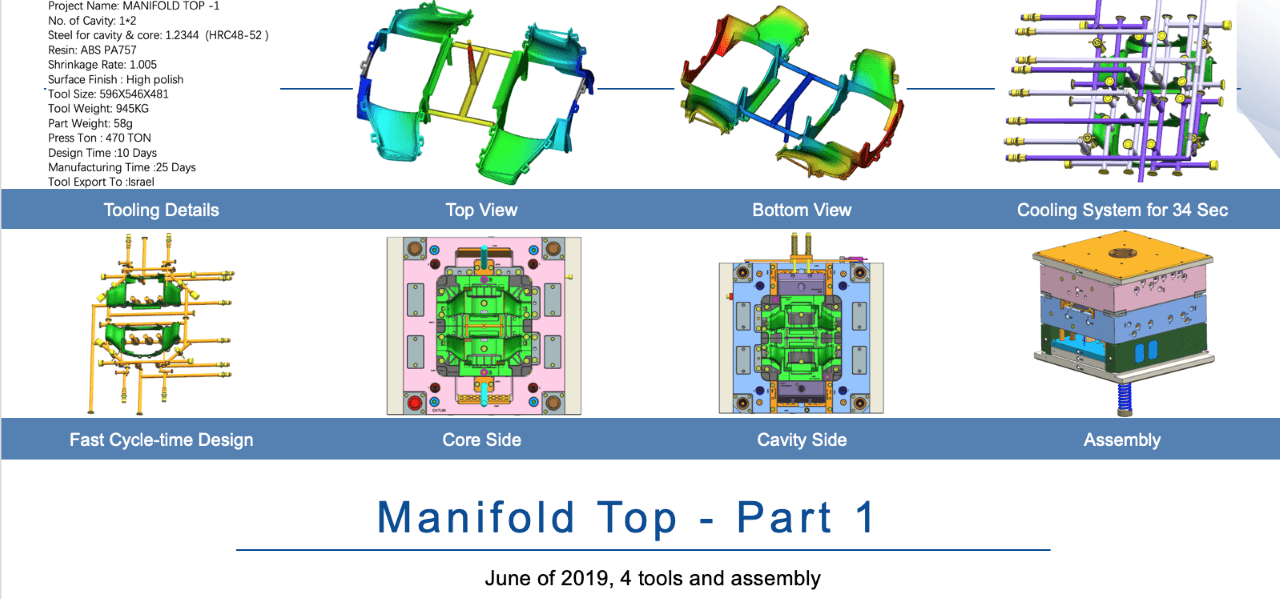

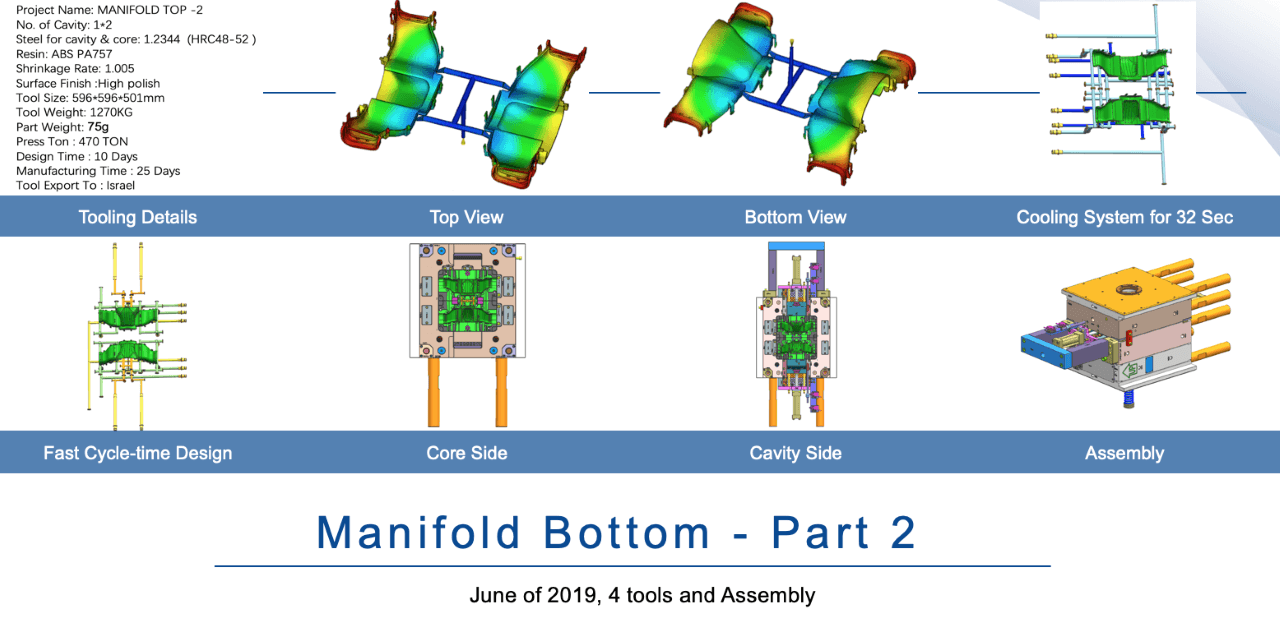

Success Story: Assembly of Manifold Top

OME build all 4 tools and supplies the subassembly to final customer in Israel.

We can help our customers by supplying single molded parts or by providing assembly services.

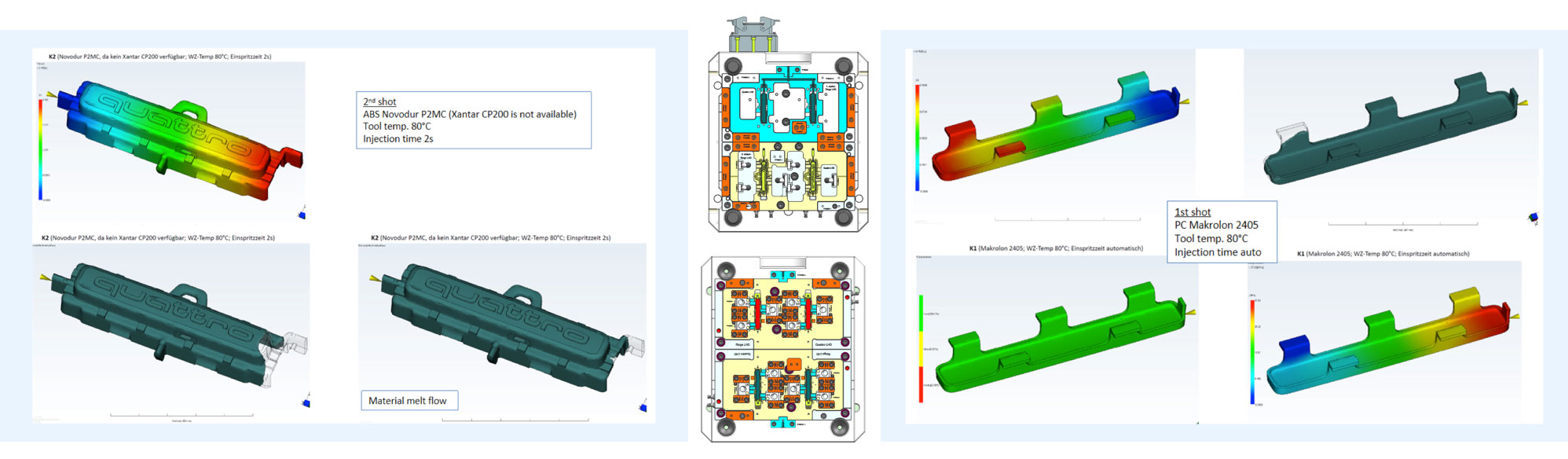

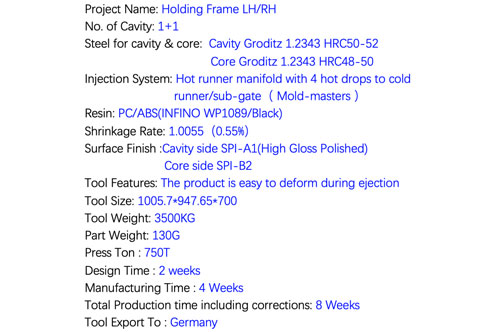

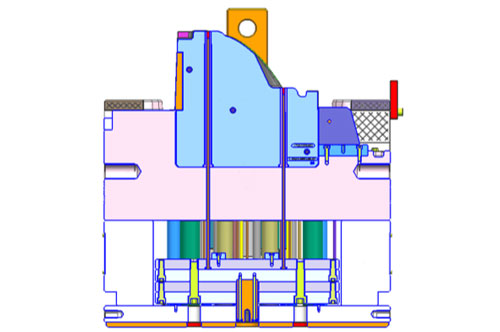

Success Story: 2K Rotational Success

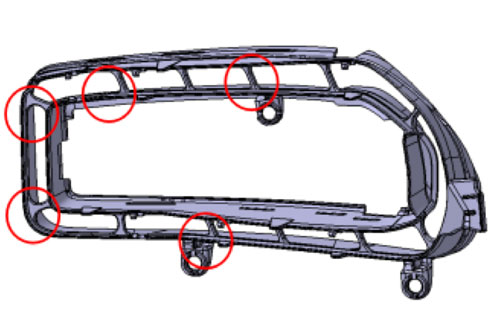

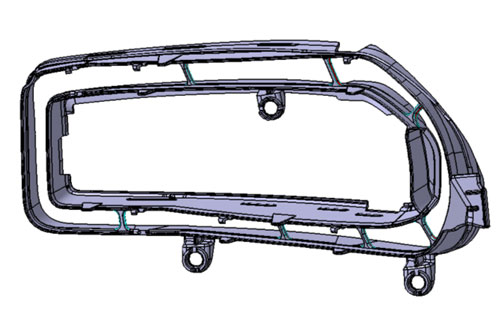

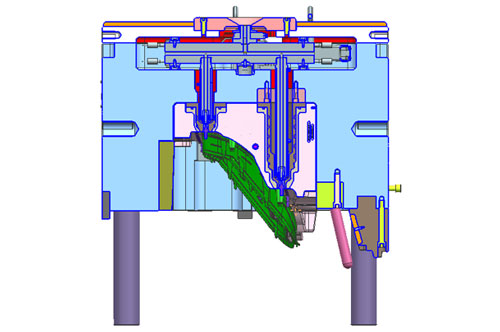

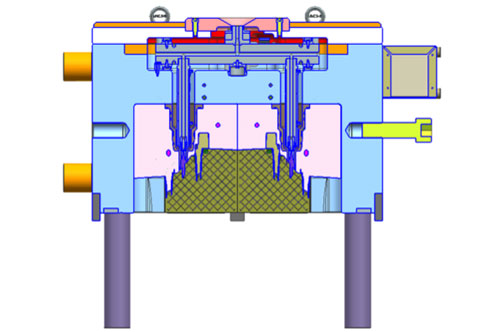

Part name: Car brand lamp

No. of Cavity: 1+1, (2-shot rotational mold)

Steel for cavity & core: 1.2343ESR (Groeditz) , HRC50-52

Injection System: Hotrunner connector configuration (INCOE)

Resin: ABS/PC & PC

Shrinkage Rate: 0.55%

Surface Finish : A-Surface (visible/cosmetic part areas) 1000 grit

B/C-Surface (partially visible or invisible part areas) 600 grit

Tool Size: 396 X 446 X 375mm

Tool Weight: 400 kg

Part Weight: 8 g

Press Ton: 110 Ton

Design Time: 2 weeks

Manufacturing Time: 5 weeks

Export: Germany, December 1, 2018

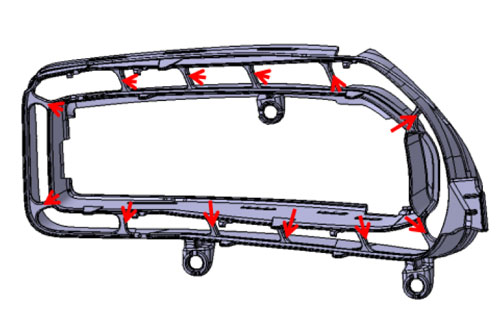

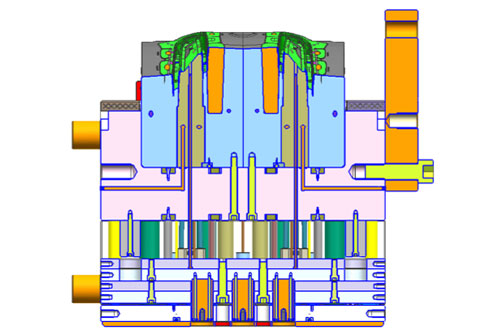

Success Story: Automotive Light Housing

December of 2018, complete program in 8 weeks including design and adjustments after T1. Program shipped to Germany for production after Trial 2.

Our recommendations resulted in elimination of distortion during ejection and reduced cycle time.