DFM & Mold Design

We provide engineering guidance to help you design moldable parts that are optimized for manufacture. From tool design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing high-quality injection molded parts.

Product Design Assistance

Support in the design of product features, specs and industrial design follow. We can support you in development of your new projects or re-design current products and implement these steps on behalf of clients by meeting in person and teleconferencing with you and your sales & marketing and technical people each step of the way.

Product Development

- Early Stage Engineering Support

- Quality Requirement Planning

- Material Selection Consultation

- Mold Concept Planning

- Part Optimizing

- Design For Manufacturing

- Cycle Time Optimization

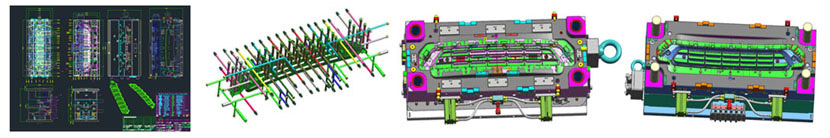

Mold Design Support

- Mold drawing 2D

- Mold drawing 3D

- Design for Manufacturable

- Mold Design Checked

- Mold Design Specification

- Mold Design Optimized

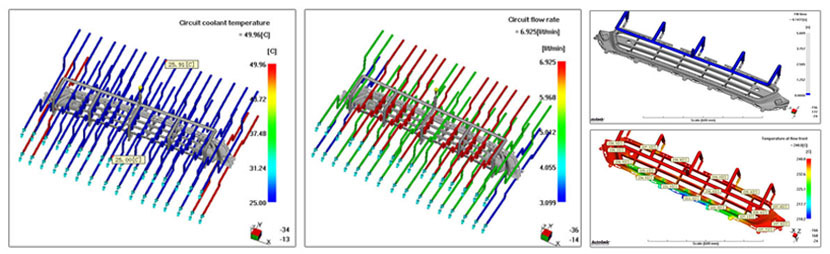

- Cooling Design Optimization

Engineering Software

- Auto CAD

- Unigraphics NX

- Autodesk Moldflow

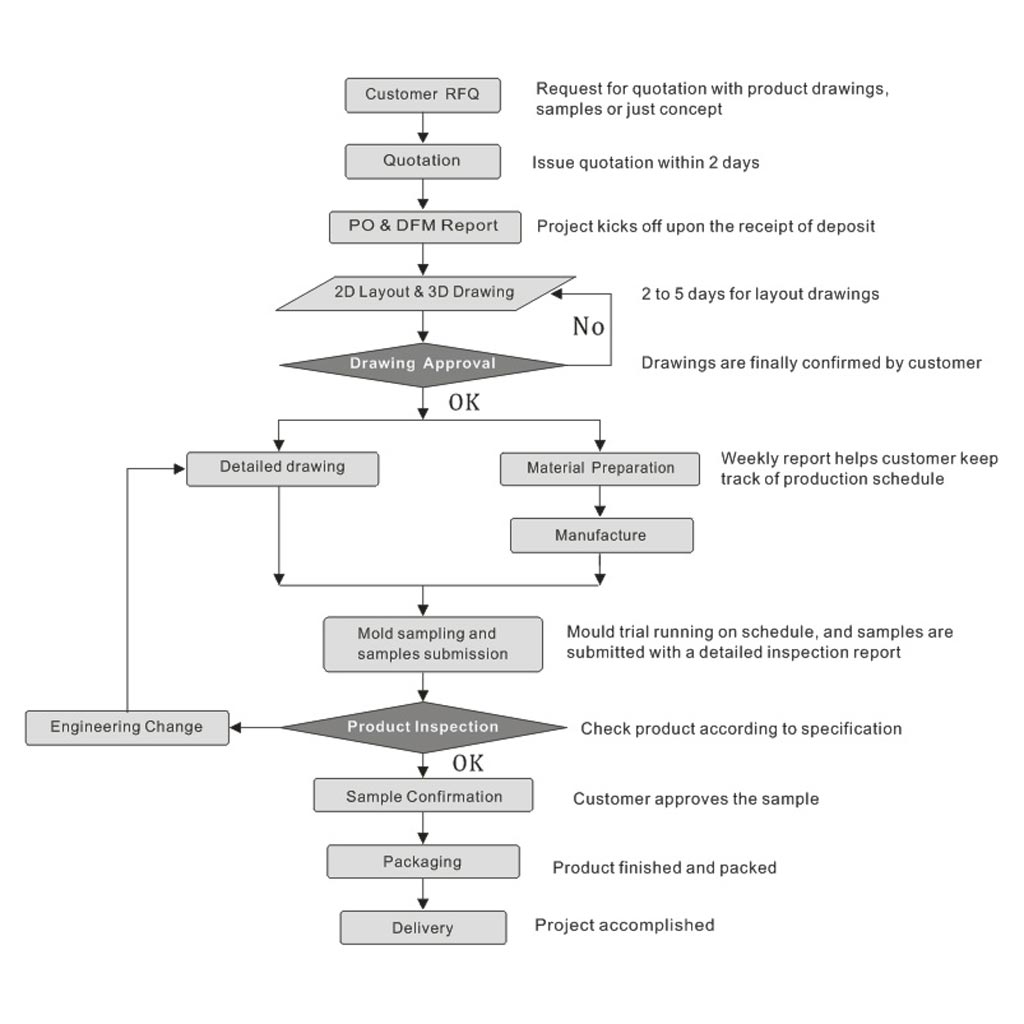

Project Management

We have six (8) professional English-speaking project management engineers to follow tooling design, tooling making and testing to provide services as below for you:

- Early Stage Engineering Support

- Quality Requirement Planning

- Material Selection Consultation

- Mold Concept Planning

- Design for manufacturability Services

- Mold flow analysis Services

- Product Testing Services

- Material Testing and Validation Services

- Product Development Services

- Product Design Assistance

- Professional Engineering Services

- Projects Schedule Planning

- Tooling Weekly Process Report

- Mold Trailing

- Mold & molding validation report

- Exception handing in logistics

Mold Manufacturing

Our mold making department is capable of constructing numerous types of injection molds with significant experience in most modern mold construction systems.

- High cavitation molds

- Appropriate hot runner design and selection.

- Low cycle molds (5000 shots)

- High cycle molds (over 10 million)

- Multi-Material molding (2k) and insert molding

- Gas Assist molding

- Foam Injection techniques

- Close tolerance Molding

- Elastomeric molding

- Compression molding

- In-Mold Labeling

- Thin wall molding

- High Heat molding

- Precise part moldings

CNC center

CNC machine (GF 5-axis )

CNC machine (Makino 5-axis )

CNC milling cutters

Mold Assembly

Makino 5-axis

GF 5-axis

ROKU-ROKU (High Speed Graphite)

Wire EDM (GF)

FANUC (Robot)

Makino EDM

Double-head EDM

Polishing

Mold Fitting

Quality Control

We are confident that our QA team will ensure the quality of your project along with the newest equipment, which we are always updating, to cater to the demand of customers.

- Mold Design Control

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Pre-Shipment Final Inspection

- CPK before mass prodcution

- Consistent quality check during production

- Quality control according to ISO 9001:2015 Quality Manual

- Export Product Package Inspection

Coordinate Measuring Machine

Injection Molding Operations

OME is a full service plastic injection molding manufacturer in custom manufacturing. With our experienced tool makers and setters, we can achieve optimal product output in a minimal amount of time. We mold your products to meet your specifications and put them trough our quality inspection department to guarantee accuracy and quality at all times.

- On-site injection plastic mold repair & maintenance

- Insert molding, dual-color molding service

- Extensive capabilities to process engineered raw materials and complex filled-polymer compounds

- Tight Tolerance and Quality Controls

- 1 Clean Room Molding (100K class) with 20 electric molding machines

- 76 Injection Machines (Range from 50-1300T, electric x24, vertical 1x, two shot x3), we can achieve optimal product output in a minimal amount of time.

- ISO 13485:2016 certified and ISO 9001:2015 certified

- Injection and SF molding with gas counter pressure capabilities

Assembly and Secondary Operations

Our team is fully capable of managing secondary operations, assembly and final packaging ready for shipment to your warehouse.

Silkscreen

Paint

Assembly

Test

Kitting

Packaging

Logistics / Finalization

Finalization is an end process by our quality team to make sure everything is ready for shipping and meets all the customer requirements and specifications.

Documentation

Complete documentation, 2D Mold Drawing and 3D Mold Drawings, trial parameters, trial video, material certifications, Dimensional Report

Final Mold Test

Depending on customer requirements we can run the tool for up to 8 hours before shipping (with resin supplied)

Specifications

Quality team will review the original customer specifications to insure all requirements have been met

Packaging

Vacuum sealed and special shipping container to prevent damage during shipment.

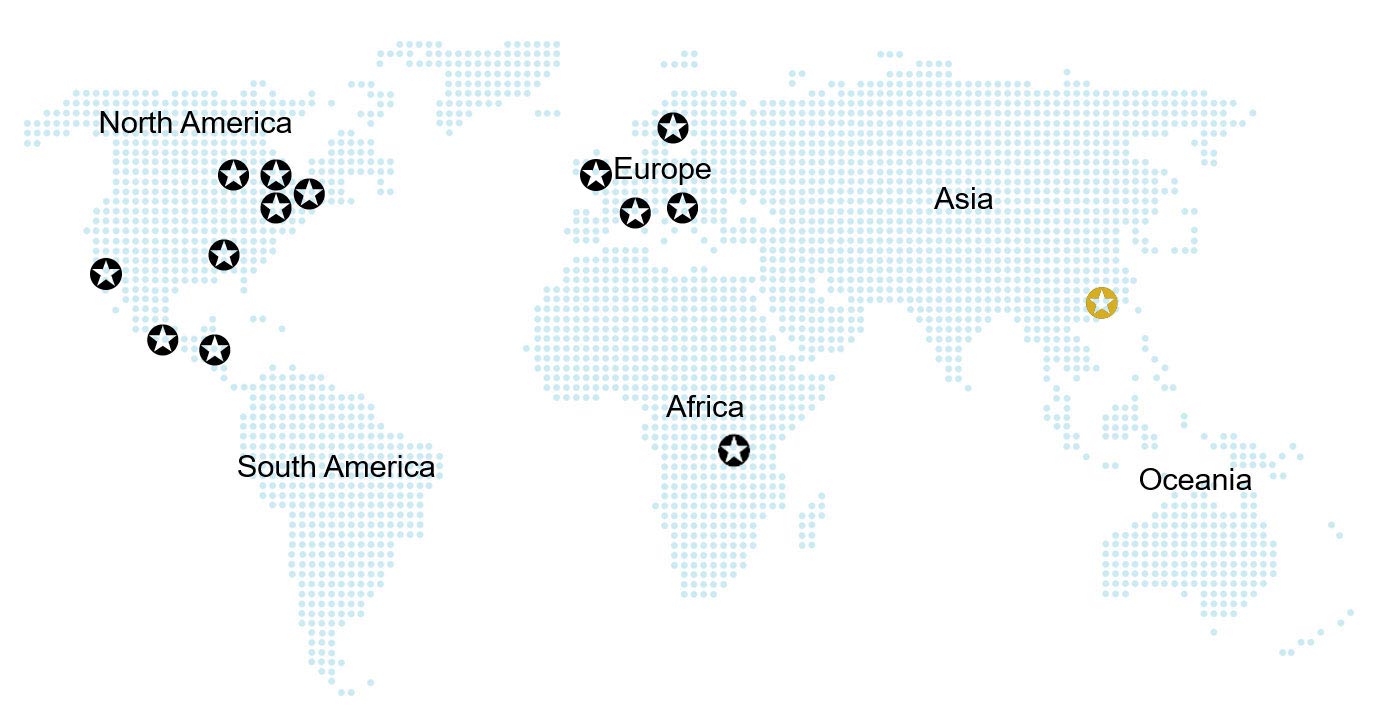

After Sales Service Network (ASSN)

Using our global network to service our customers around the world.

OME America’s Division.

Ravi Mirchandani-President

7323 Royal Oaks Court, Pleasanton, CA 94566 USA

Tel (510) -436 -9629

ravi@ome-mould.com

130 Parkway West

Duncan

South Carolina

29340, USA

1307, Bergar Street

Laval, Quebec

H7L 4Z7, Canada

1905 Blackacre Drive

Oldcastle, Ontario

N0R 1L0, Canada

Langer Mexico

Corral de Piedras No. 76

Poligono Empresarial

San Miguel de Allende, Guanajuato

37888, Mexico

Peartec s.r.o.

Krašovská 2265/7

323 00 Plzeň 1

Roush Global Tooling

34300 W. Nine Mile Road

Farmington, Michigan

48335, USA

Beckert Modell und Formenbau GmbH

Hanns-Martin-Schleyer Str. 3

Bad Friedrichshall

D 74177, Germany

Avery Products Corporation

Todos los Santos 7651,

Parque Industrial Pacifico

Tijuana California

22643, México

Superite Tools Ltd, (UK & EU)

Craig Dingle

OME Technical Director

Walsall, West Midlands. WS9 8UG.

Region = Sub-Saharan Africa

DeansDesign

shaundean.za@gmail.com